Unit soles

PROVEN DESMA TECHNOLOGY – COMPETENCE IN UNIT SOLE MANUFACTURING

Unit sole machines are offered for the materials of Rubber, PU, TPU and other thermoplastics.

Combinations of materials or making multi colour soles of the same material is possible.

POLYURETHANE POURING

Automatic pouring system – Sole production in a cycle of seconds

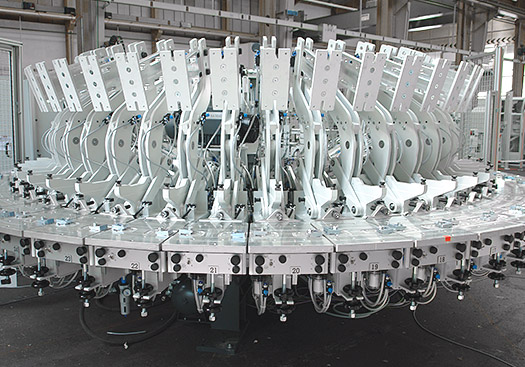

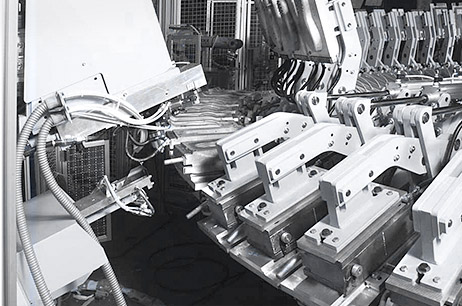

DESMA S 511

Rotary table desma S 511/60 with 60 stations for different applications including DESMA’s newest polyurethane mixing technology.

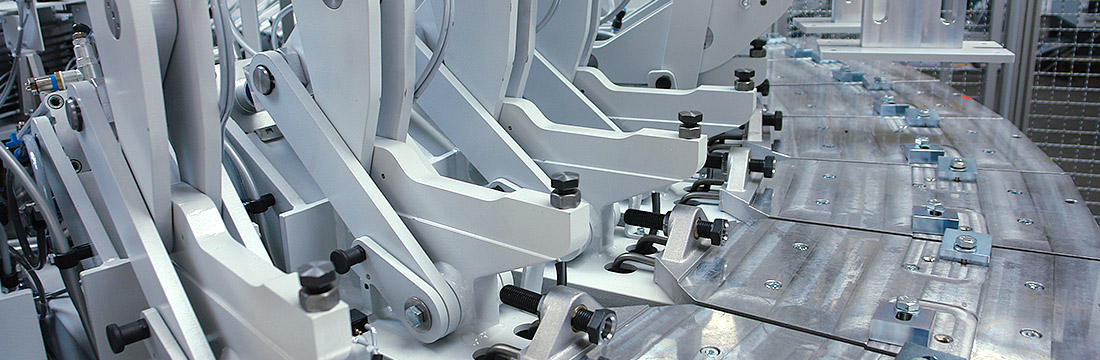

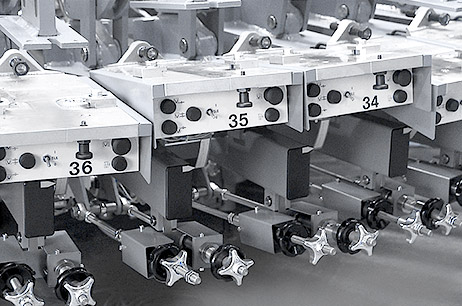

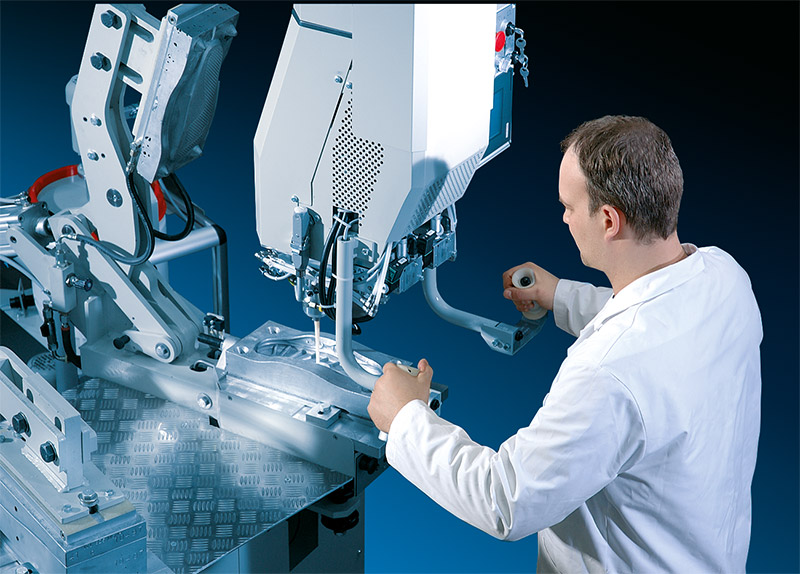

MANUAL SWIVELLING OF CLAMPING UNITS

AUTOMATIC SWIVELLING OF

CLAMPING UNITS (OPTIONAL)

DIRECT SOLING ONTO SHOE UPPERS

(OPTIONAL)

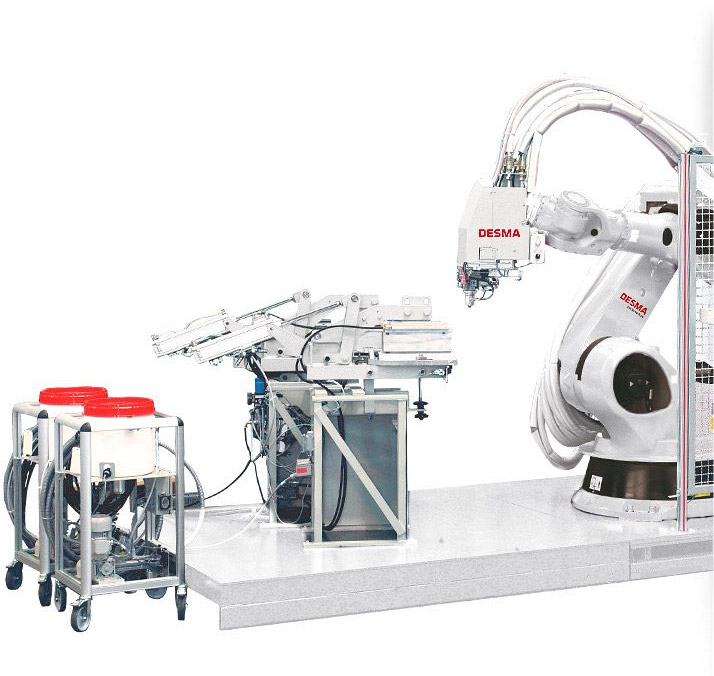

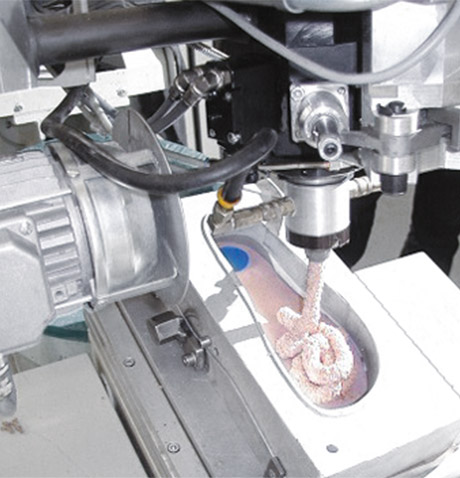

Robot-guided pouring system

TOP PERFORMANCE

- all-in-one-control for robot

and machine - pictures lead the way to all important

machine functions - simple and easy operation

- quick trouble-shooting through self

diagnosis of the complete system - teleservice on all important

machine functions - all desma pu pouring heads are self-

cleaning and do not require any type

of solvent flushing

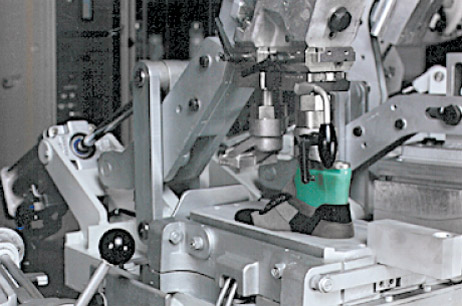

Manually operated pouring system

COLOUR CHANGING

- high flexibility due to precise colour dosing

- quick colour change from shot to shot

- quick exchange of colour carts for

- additional colours possible

MANUAL PU POURING

- self-cleaning mixing chamber

without the use of solvents - exact adjustment and control of the

mixing conditions - precise adjustment of the mixing gap

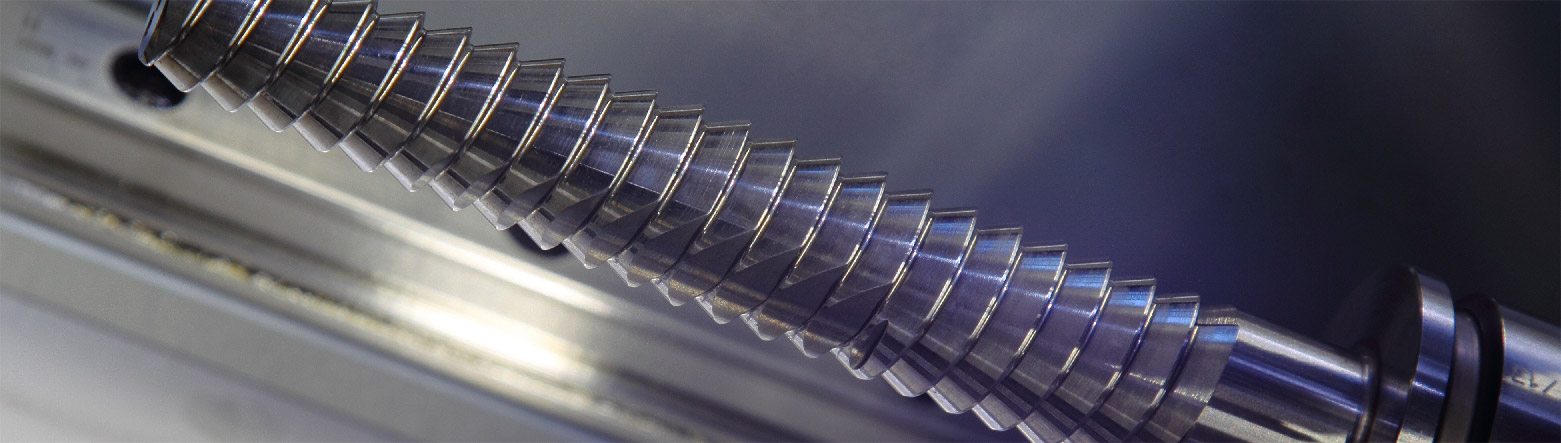

for any pu-material - exact adjustment of the screw position

for mixing and cleaning operations - fast screw clamping system

- setting of individual throughputs

for every mould - bulk filler dosing system for pu-waste,

cork OR granulated material and/or powder - colour dosing units for dosing of up to 4

colours directly into the mixing chamber - flexible production with 2 or 3

main components - mixing screws and mixing chambers

for throughputs of up to 120 g/s

Granulate dosing (optional)

Adding various types of granules directly into the mixing chamber

ECONOMIC ADVANTAGES

- pu waste can be fed back into the stream of poly and

iso through the granulate system - material waste is reduced to an absolute minimum due

to high precision machine operation - clean, reacted pu waste (or cork and others) may be dosed

with liquid polyurethane components in an environmentally

friendly process