Boots

INDUSTRIAL PU BOOT MANUFACTURING

Over 75 years experience is the foundation

for every DESMA machine.

DESMA develops complete production concepts for industrial PU boot manufacturing together with the customer. We help you to create a colourful world through ?exible and swift colour dosing from boot to boot.

High productivity with DESMA technology: your way to success.

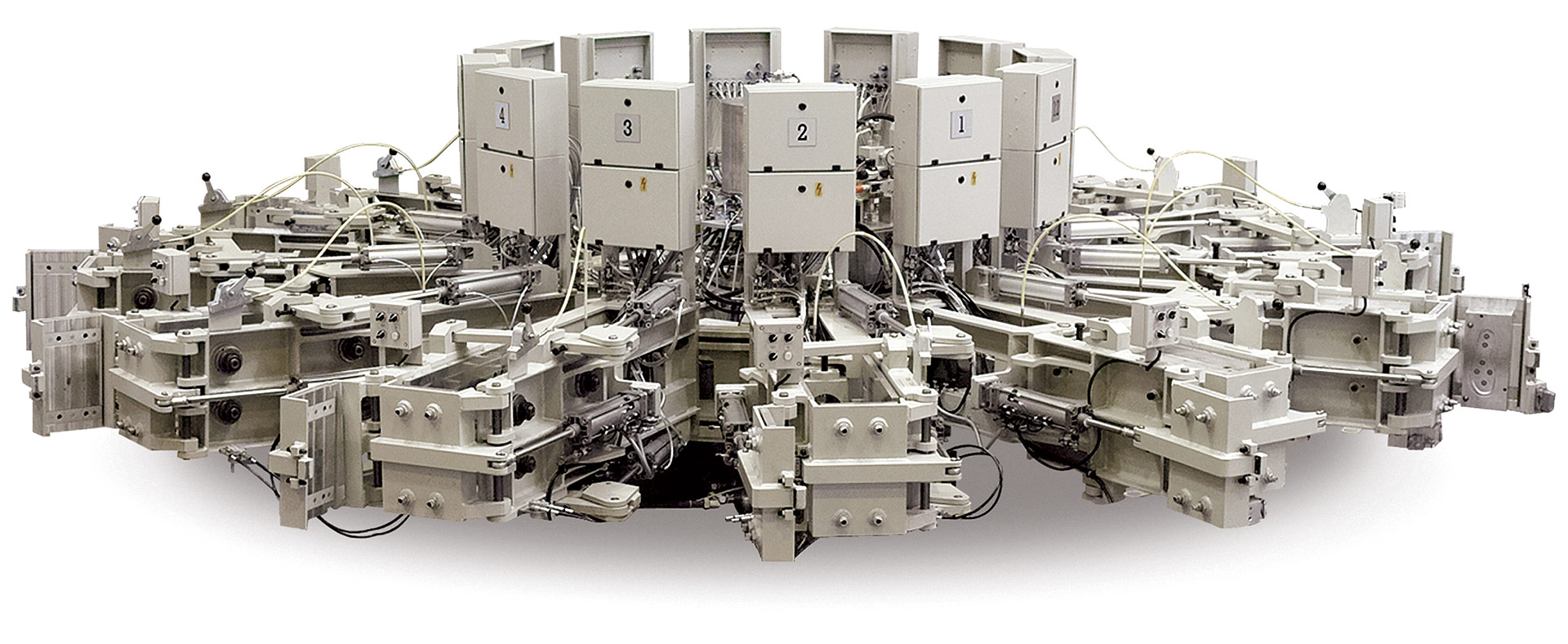

B 512/12

Made in Germany

Countless features are typical of DESMAs solid engineering.

Each boot machine – finely tuned to the customer’s individual needs – is characterized by economy, efficiency, flexibility and highest quality demands combined with a reliable and robust construction. DESMA’s high safety standard is always ensured. Rotary tables with 10 or 12 clamping units are based on a modular principle. The proven Maltese cross drive turns the table in cycle time. The central energy distributor provides temperature medium, compressed air and electricity to each clamping unit.

Many optional extras are available, providing an optimum mix of high automation and manual possibilities. Ergonomically favourable working conditions are an important aspect considered in the design and construction of DESMA boot machinery. All operations are carried out at normal working height, platforms or gullies are not necessary. Optimal working conditions guarantee ideal production conditions for industrial PU boot manufacturing.

B 512/12 FACTS

- robust construction

- high product quality

- high clamping force

- modular construction concept

POLYURETHANE (PU)

Lightweight with polyurethane

Polyurethane boots for

- agriculture and construction

- food industry

- safety boots with protective toecap

and steel sole

Polyurethane, with its excellent characteristics for the footwear industry, has been steadily growing in importance over the last 40 years. Boots from foamed PU are up to 40% lighter than comparable boots of rubber or PVC. Excellent insulating qualities are ensured by millions of tiny air bubbles within the polyurethane.

PU also offers splendid comfort for the wearer, due to its flexibility. There are various PU materials and material combinations for different applications, e.g. PU/PU, TPU/PU or Rubber/PU. One constant is the soft, elastic boot upper combined with a compact, abrasion-resistant sole providing high slip resistance on all surfaces.

Unique qualities of PU

- utmost comfort

- low weight

- anti-slip

- flexible at low temperatures,

heat-resistant - fulfils all norms for safety

and work boots

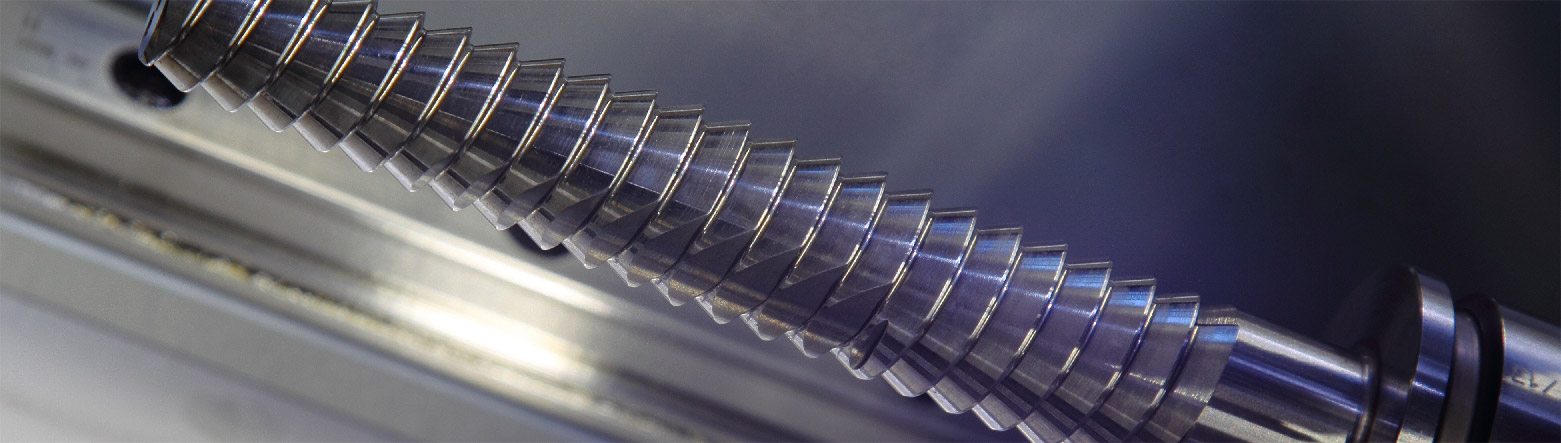

PU MIXING TECHNOLOGY

Lowest environmental impact

DESMA PU machinery needs no rinsing agent in the mixing head: a clear advantage. The self-cleaning head ensures cleanliness and robust production. DESMA PU reaction machines are characterized by an especially reliable process technology. DESMA mixing heads have synchronously-controlled mixing head valves and extremely precise temperature regulation. Mixing ratios are exactly adhered to.

PU COLOURING

Production processes may be simplified and rationalized with a variety of optional accessories: colour change from boot to boot during running production is possible. Also simple: the change to a different material.

PU MIXING HEAD WITH MOUTH PIECE CLEANER

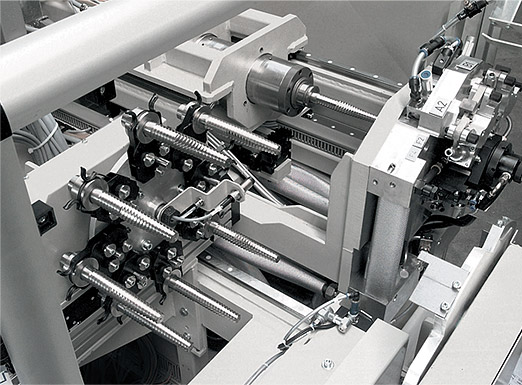

AUTOMATIC MIXING SCREW CHANGE

COLOUR CARTS

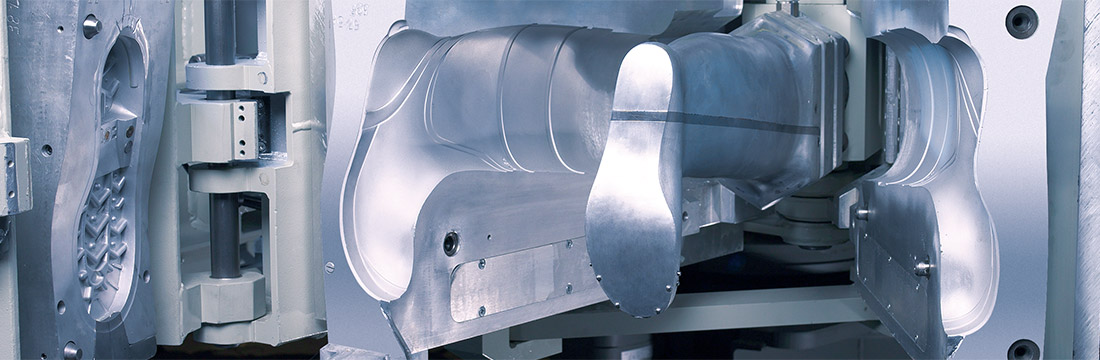

Clamping Unit

A strong connection

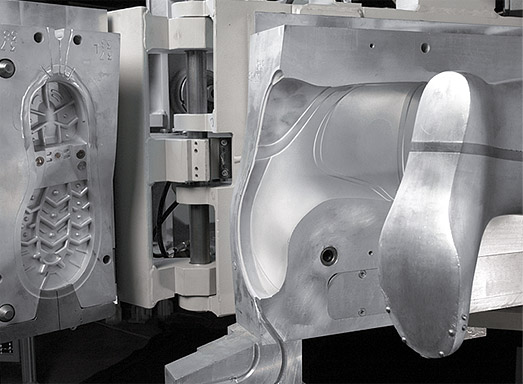

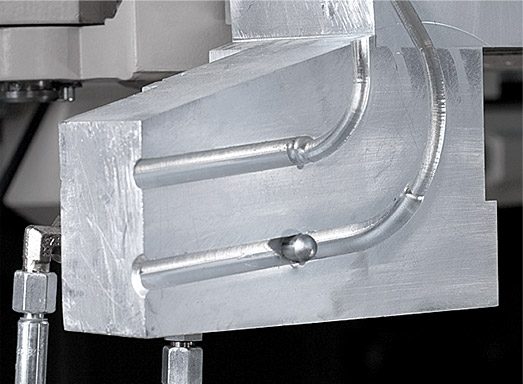

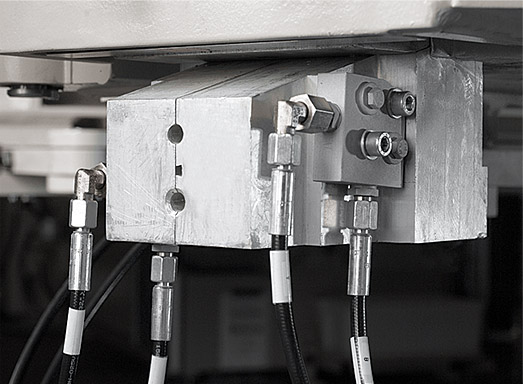

Clamping units are held by hinges and assembled horizontally on the rotary table. The ergonomical, operator-friendly clamping unit has a large opening distance, linings may be easily lasted. The finished boot can be de-lasted easily using compressed air or the divided last option. All closing and opening movements are controlled pneumatically, except the hydraulic lock for the PU injection channel. In the first step, the foamed upper material is injected into the closed clamping unit. The powerful hydraulic lock hinders backflow of material. Before the PU sole is injected onto the boot upper, the lid plate is exchanged for the engraving plate. All opening and closing movements are automated. TPU soles and rubber soles are manually placed.

MOULD CARRIERS

Fast Mould Change

Both mould parts and the last are installed and removed together as a package through the slightly opened clamping unit. The side mould fixations are anchored by two exterior screws. Last fixation is provided by a bolt.

Speed is ensured by the pre-mounting of sole moulds on fixation plates.

BOOT DE-LASTING

Advantages of horizontal lasting

- boot height up to 500mm

- lowest risk of air entrapment

- low flash injecting

- easy sock lasting

- regular and thin boot upper thickness

- easy de-lasting

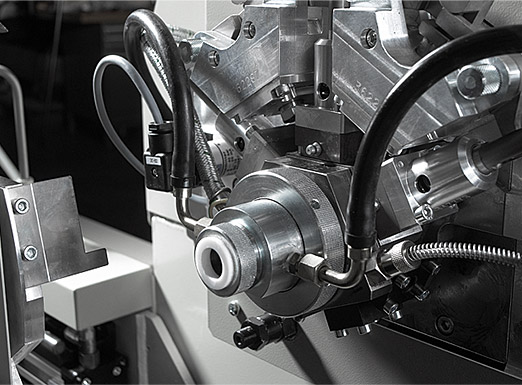

INJECTION SYSTEM

INJECTION LOCK

Unique DESMA low pressure technology

DESMA offers footwear manufacturers a comprehensive technical consultancy and helps with layout projections. Highly qualified DESMA staff are happy to help with expert advice on polyurethane processing and process technology. We trim the technology, the PU material, the moulds and the process to the type of boot required and production restrictions.

Customer trials may be undertaken in the DESMA Technikum with its own laboratory. Our service team is available for our customers, worldwide.