Latest news

28. November 2019HOW CUSTOMER WISHES TURN INTO PRODUCTS

DESMA Showroom is one of the first ports of call for customers and internal inquiries – Large variety of services: sample production, material tests, automation tools – Robots and laser facilitate shoe production

How practical: having shoe samples produced without having to interrupt your own production processes, or the chance to test different materials and methods without having to use your own machinery. This is all possible at the DESMA “Showroom” in Achim. Since 2017, the Showroom has been used by all footwear manufacturers – from adidas and Birkenstock to Uvex – and by material suppliers such as BASF. It is also appreciated by DESMA’s own departments, such as mouldmaking, sales and training. “We provide services relating to all aspects of footwear production for a large number of external and internal customers,” says engineering graduate Martin Orthey, who is responsible for sampling and training.

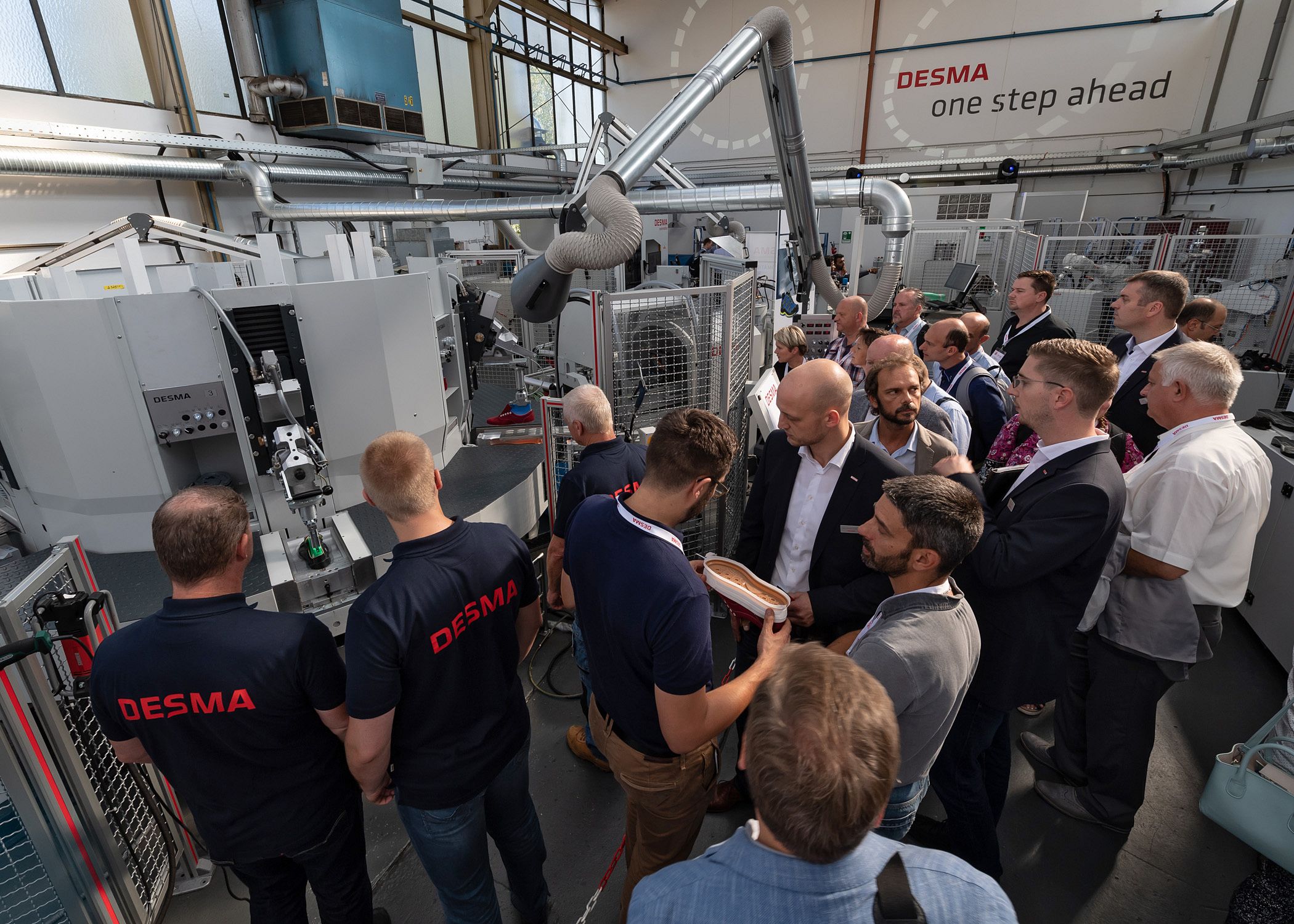

Step into the Showroom in Hall 12 and you immediately see the modern technology that is in standard use at DESMA for industrial footwear production. The Showroom provides a platform where shoe specialists, engineers and designers can test the latest technological trends and materials, produce prototypes and try out processes in a real production environment. By offering this facility, DESMA shortens the lead time required until series production and market rollout. “Customers can see at first hand how the shoes of the future are developed and how state-of-the-art processes are applied to monitor comfort, quality, cost effectiveness and design. This has triggered many a eureka moment and given customers the edge over their competitors,” says Orthey.

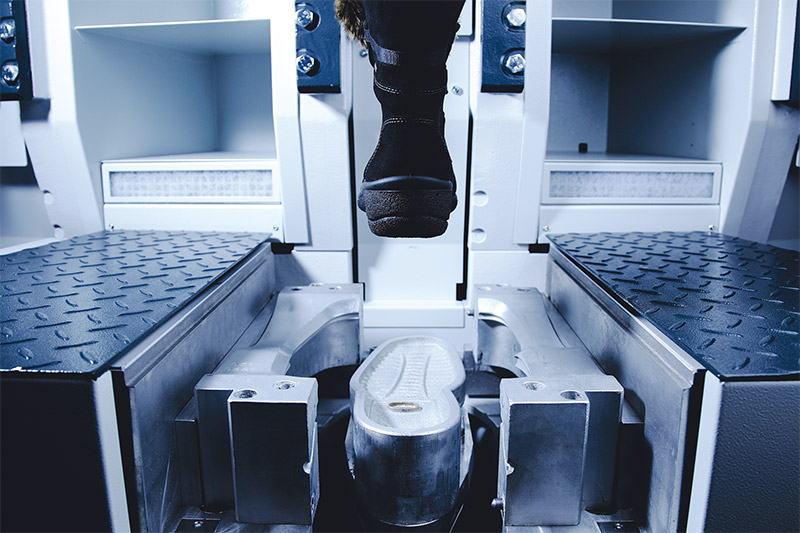

DIRECT SOLING MACHINE MEETS ROBOTICS

The heart of the Showroom is the direct soling machine, which moulds soles made of polyurethane and other synthetics directly onto the uppers. This is where we produce prototypes and small batches for customers or test new production methods. “For our customers, these outsourced test runs have the advantage that they can try out new ideas without having to disrupt production at their own factories. Under the guidance of our experts, they can try out various moulds, colours, materials and uppers, giving them the chance to identify and remedy weak points at this early stage. This greatly simplifies the subsequent configuration of the machines,” explains Orthey. The DESMA sales department also uses the rotary table in the Showroom to produce samples for potential new customers.

The DESMA mouldmaking department uses the plant to test moulds for the manufacture of sample shoes before the moulds are delivered to the customer. To DESMA, this is not merely a part of quality control, but actually a unique selling proposition, as none of its mouldmaking competitors has a direct soling machine.

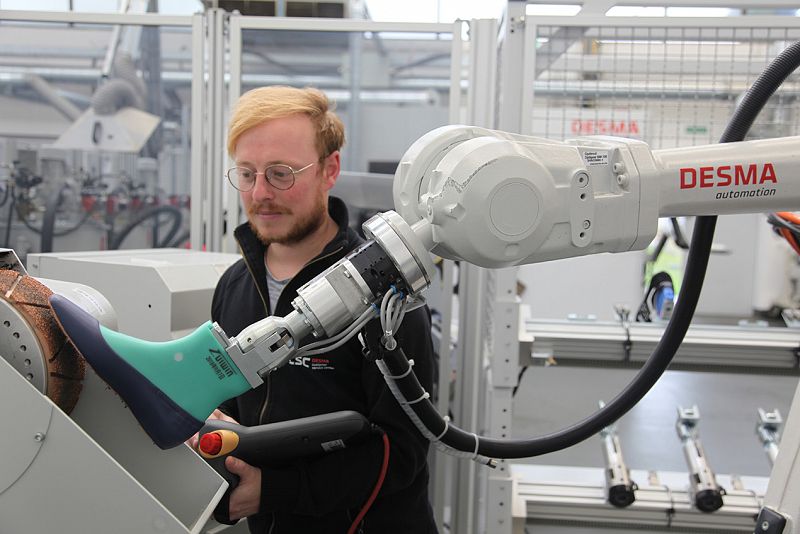

Apart from its direct soling plant, however, DESMA also provides support for conventional footwear producers in the form of automation tools such as the amir production line (Automated Material supply with Integrated Robots). This is all part of its strategy to implement Industry 4.0., where robots supplement the rotary table and make it possible to produce customised shoes and automate work processes. Each shoe comes with a QR code or RFID chip so that the robot knows what it has to do. “The robots and laser cells attend to preparatory steps such as roughening the soles, applying the adhesive or inserting decorative elements,” explains automation expert André Kroker. The application engineer travelled the world as service engineer for many years and then acquired special knowledge of automation before joining the team of five in the Showroom where he can put his comprehensive expertise into practice.

The Showroom equipment also includes an injection moulding system for various material mixes, as well as a sole cell which produces the outsoles and midsoles. “We offer a unique modular system. Depending on the requirements involved, several customers can conduct their test runs simultaneously. In 2019, more than 200 customers made the most of this opportunity,” says Orthey. All the machines are also available for training purposes, for customers and also for DESMA’s in-house service engineers and trainees.

MAKING MACHINES COMMUNICATE WITH EACH OTHER

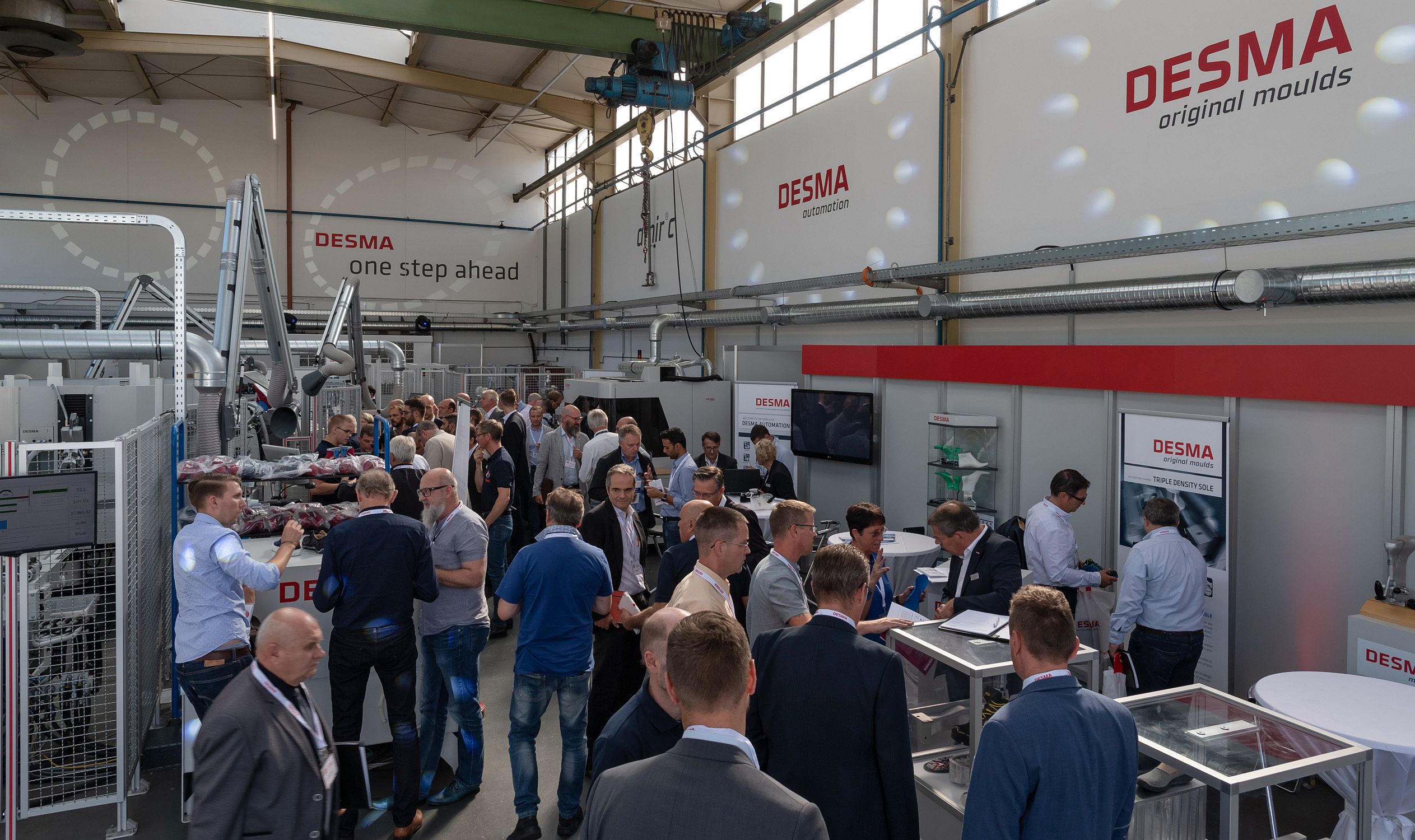

The Showroom is part of the DESMA Customer Service Center (CSC), which is where all services for our customers converge: from field sales staff and smart remote service (teleservice) to spare parts supply and even staff training. The CSC was inaugurated during the 2017 “Techniker Tage”, the technical fair hosted by DESMA. “In the past, sample production as well as research and development were based in one department. By separating them into different rooms, the public Showroom and the Innovation Center, we are now able to respond to customer requests far more flexibly and have more capacity for developing new procedures,” states CSC Manager Jörg Zilz.

DESMA Managing Director Klaus Freese adds, “The Showroom has expanded the practical support that is available for our customers. It offers a unique combination of the four key production factors: equipment, expertise, material and design. These form the basis for excellent direct soling and automated footwear production – and consequently for the success of our customers.”

And what are the future plans for the Showroom? “We are in the process of implementing Industry 4.0. What this actually means is that our robots will interact even more closely, which will continuously open up new opportunities,” claims Martin Orthey.

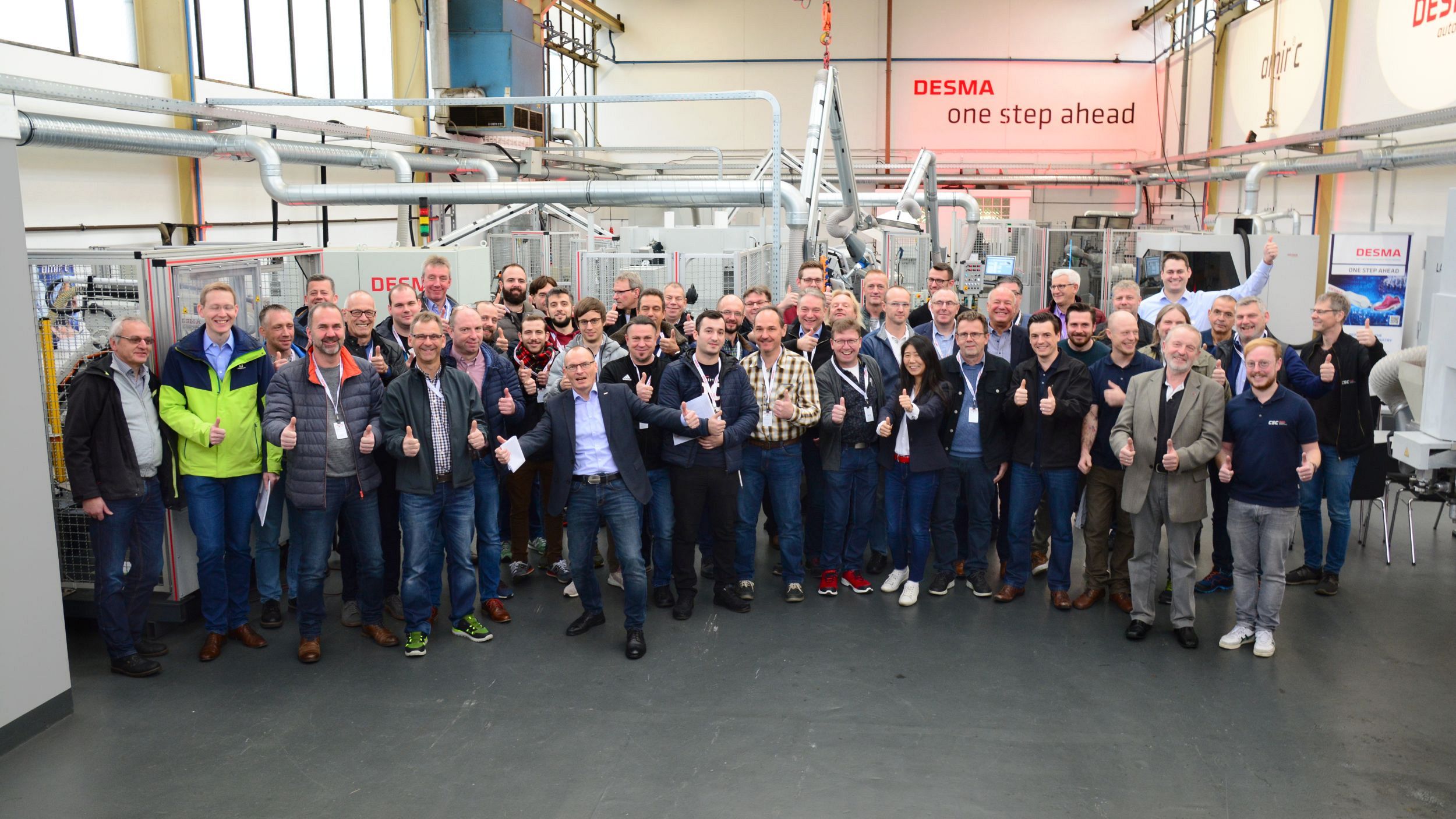

By the way: Initial information about the next steps were provided at the “Techniker Tage”, the technical fair which DESMA hosted from 26 to 27 November. 33 technical experts from the German-speaking footwear community came to Achim to find out about the latest technologies, exchange experience, attend hands-on workshops and provide feedback for DESMA – in other words, a win-win event for everyone involved.

back