Latest news

25. September 2020TRENDS IN FOOTWEAR PRODUCTION

Design, automation, variety, cost-effectiveness and resource-saving production: the footwear industry is facing enormous challenges which DESMA can help to address with its machines, services and innovations.

The footwear industry is facing dramatic changes all over the world, as customers are increasingly demanding a huge range of models and designs, customised functions and the use of highly diverse materials. The trend towards customised shoe production in particular has far-reaching consequences, with steadily decreasing batch sizes. Thanks to DESMA machinery, however, mass customisation has already become reality.

At the same time, footwear manufacturers, regardless of whether they produce sports shoes or work footwear, leisure or children’s shoes, business, trekking or women’s shoes, have to reconcile the growing demands of their customers with production processes which are not only cost-effective, but which also ensure minimum impact on the environment and natural resources. This balance can only be achieved with automated processes and the use of innovative technologies. And this is where DESMA can help with its innovative production solutions (Industry 4.0), highly automated machinery, professional excellence and comprehensive support.

Direct soling: core technology of cost-effective footwear production

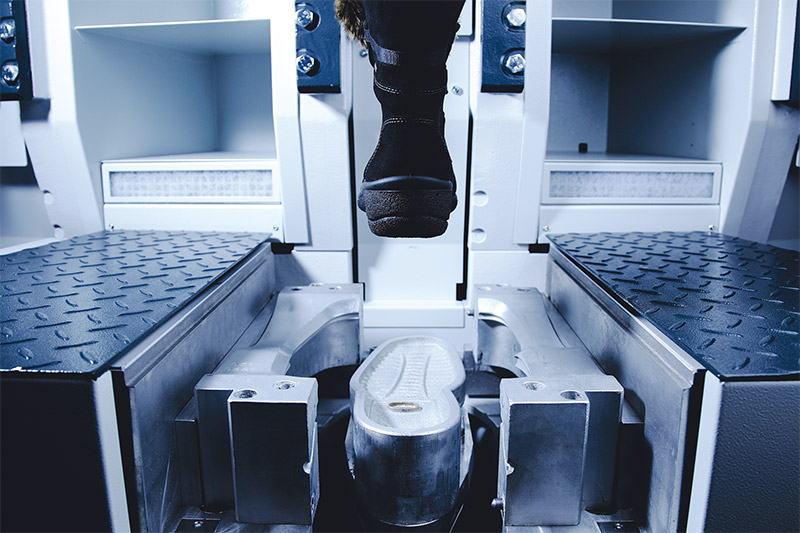

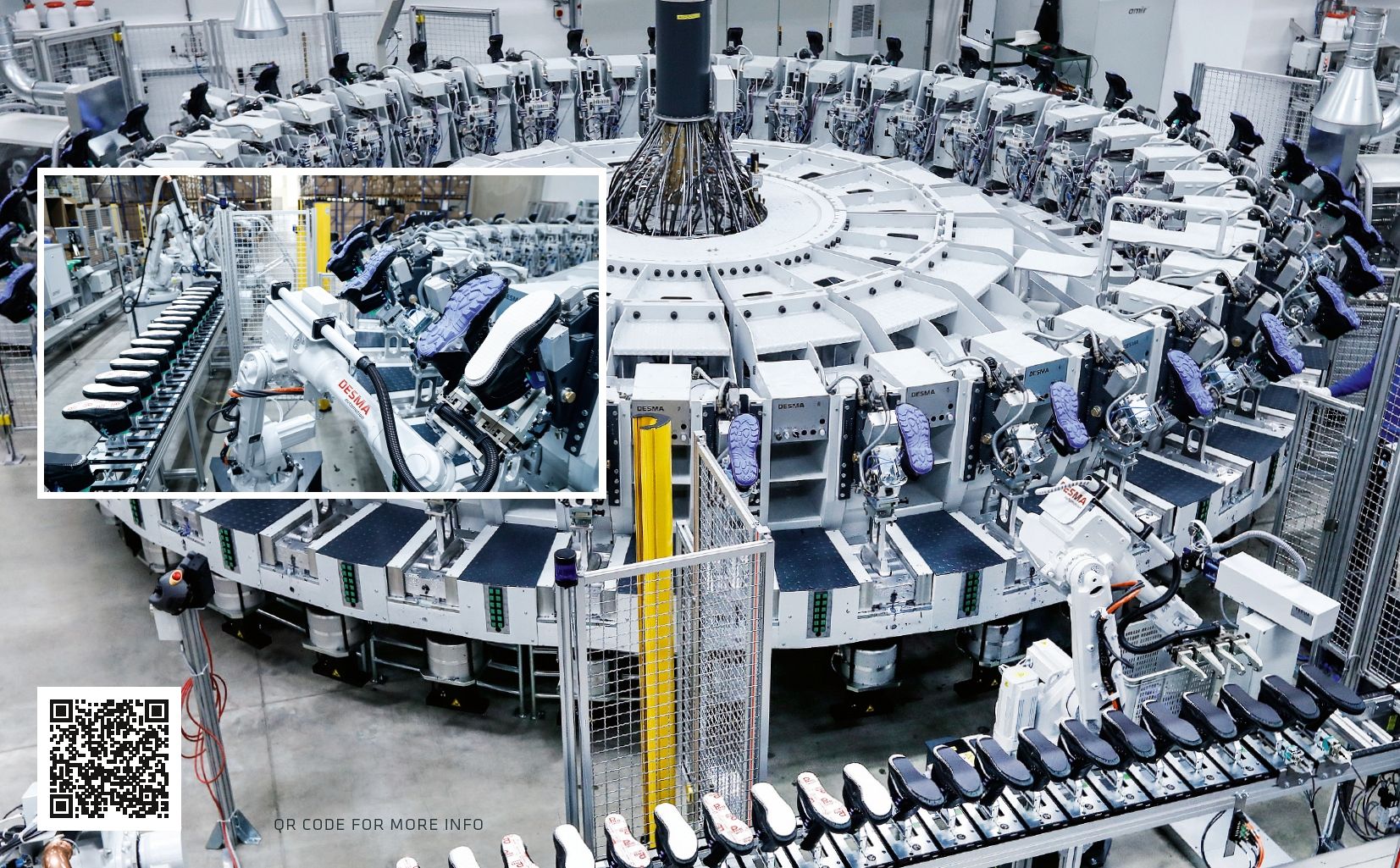

The heart of the DESMA portfolio is its direct soling systems, which mould soles made of polyurethane, rubber, thermoplastic polyurethane or other synthetics directly onto the uppers. DESMA rotary tables with 12, 18, 24, 30 or 36 clamping units are designed as modular systems which can be equipped with a large variety of extras, enabling them to deliver the optimum mixture of a high degree of automation and manual functions. The sole material is directly injected and combined with the upper, thus ensuring perfect adhesion between upper and sole. The sole material surrounds the upper, which means there are virtually no limits when it comes to designing creative soles, different combinations and special effects.

DESMA innovations: MSI, centre wedge and DESwing

In response to the trend towards customisation, DESMA has developed Multi Section Injection (MSI) technology, for example. Material injections into various sections of the sole can achieve different properties, such as hardness; what’s more, this can be individually controlled, changing from shot to shot. This offers the wearer optimum comfort, energy absorption and stability. Special design effects can be achieved as it is now possible to use different colours in the individual zones.

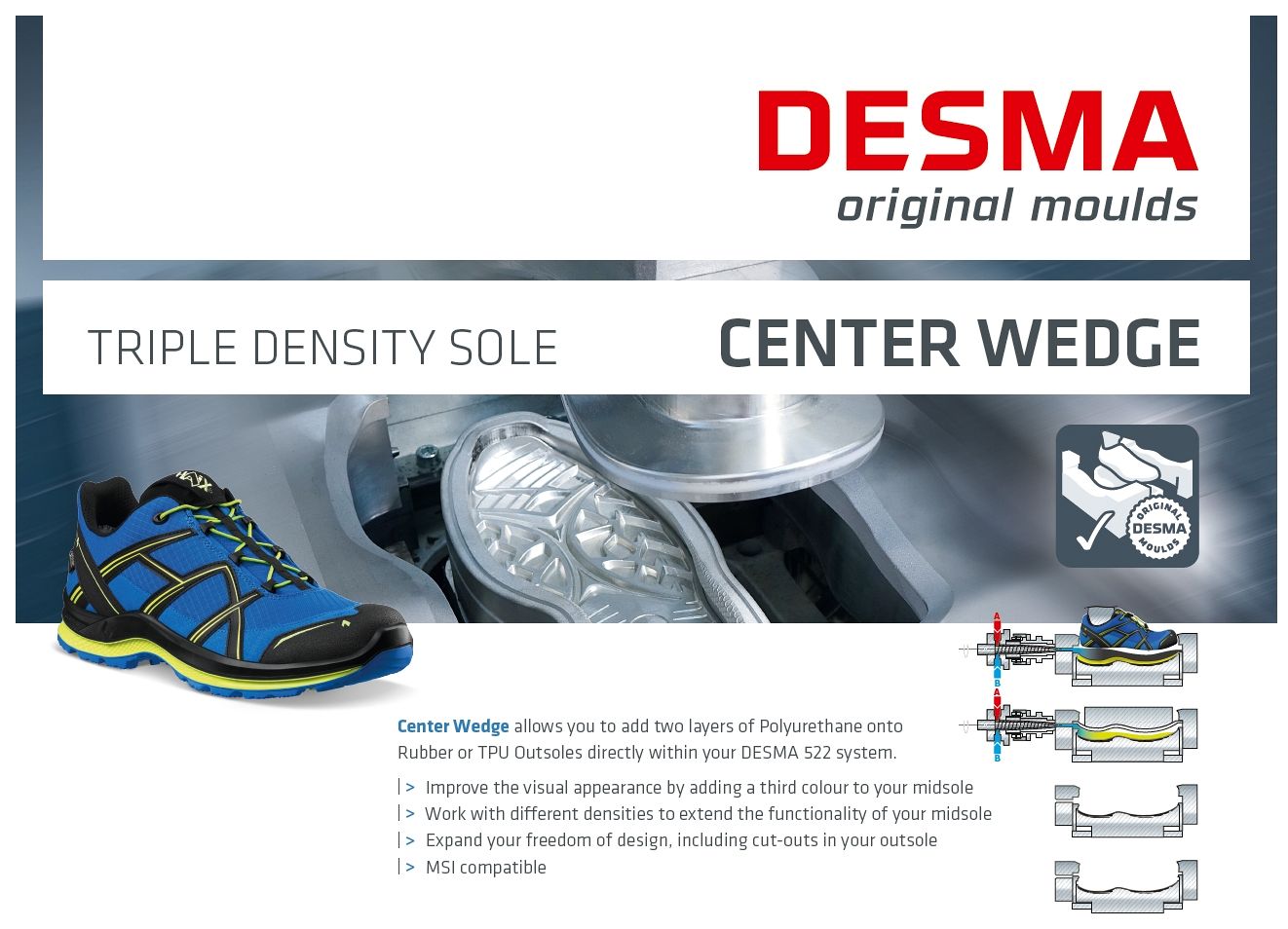

Two new processes called Centre Wedge and DESwing now make it possible to enlarge the range of design options and/or the range of features for multi-coloured soles as well as the mix of different materials. These new methods are achieved in a combination of mouldmaking and machine control, delivering a wide range of benefits for the customer. DESMA has also developed an In-Mould Labelling process in which the use of integrated plastic sheeting or textiles creates new product varieties for the outsoles, giving a virtually unlimited choice of colours and colour effects for the shoe.

Industry 4.0

Apart from its direct soling plant, however, DESMA also provides support for footwear producers in the form of automation solutions such as the amir production line (Automated Material supply with Integrated Robots). This is all part of its strategy to implement Industry 4.0., where robots supplement the rotary table and make it possible to produce customised shoes and automate work processes. The shoes or lasts are equipped with data carriers so that the robot knows what it has to do. “The robots and laser cells attend to preparatory steps such as roughening the soles, applying the adhesive or inserting decorative elements,” explains DESMA Managing Director Klaus Freese. “Our automation solutions support our customers in a number of ways,” he explains. “Robots and automated systems work precisely and in consistent, reproducible processes. This not only improves quality, but also reduces costs.”

Environmental protection and efficient production

DESMA enables its customers to produce footwear efficiently, even in high-wage countries. Moreover, the optimum use of materials and resources promotes eco-friendly production. DESMA machines thus help the footwear industry to adapt flexibly in response to rapidly changing market conditions.

back